Machine Upgrade – Weight Checker

Project Overview

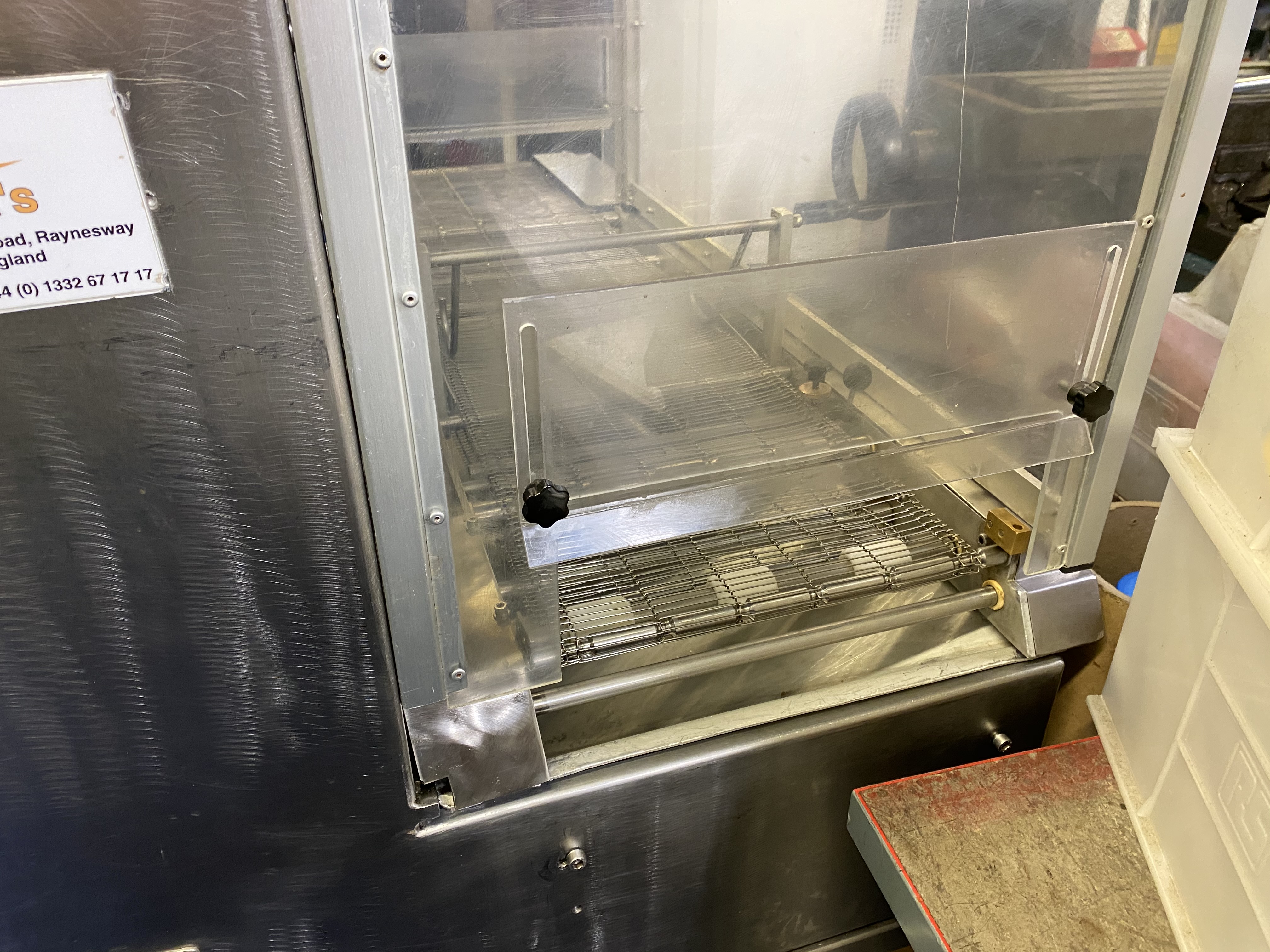

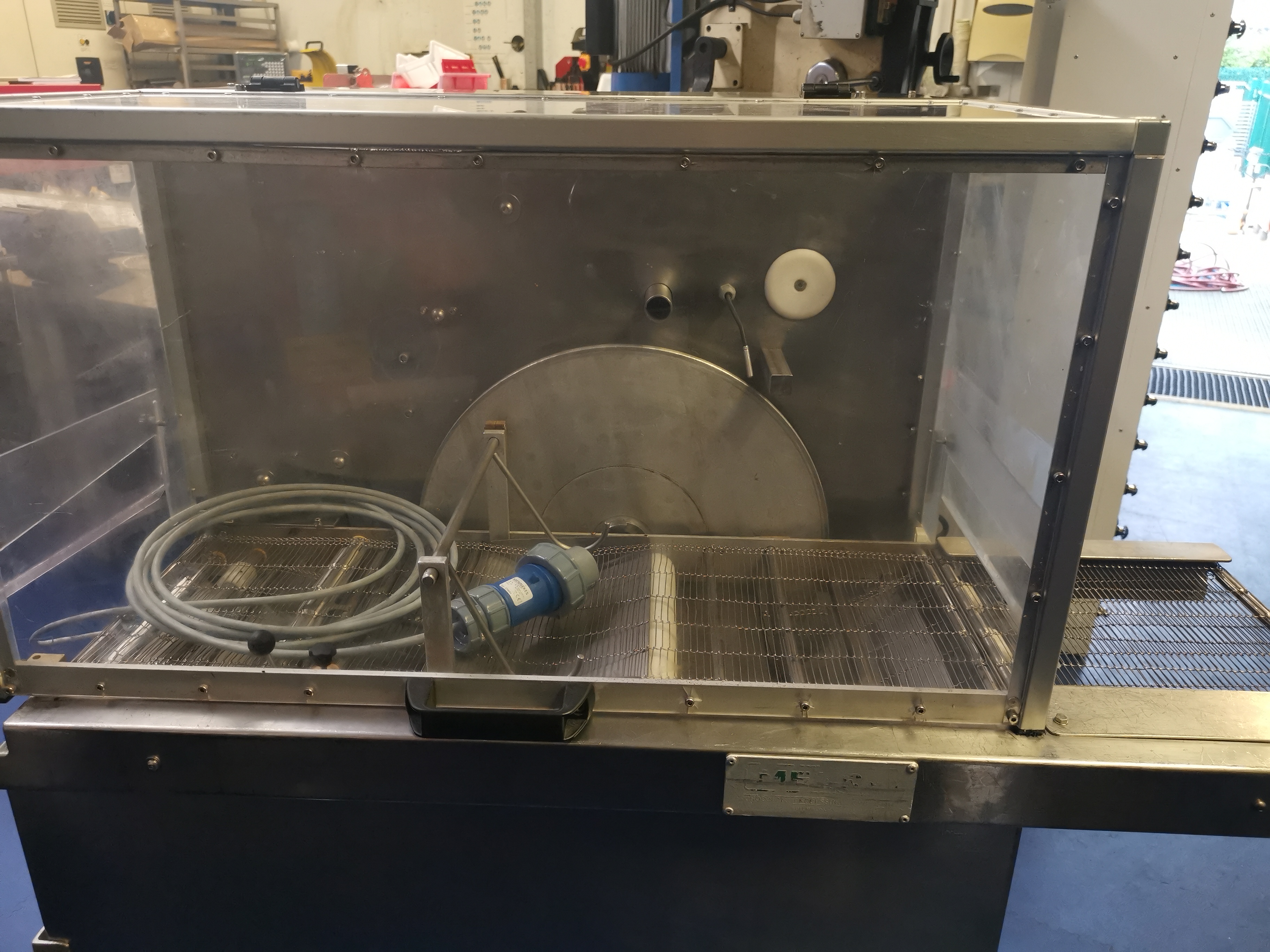

Our customer required a modern, reliable solution for counting and weighing a wide variety of cheesecakes. Their existing system lacked precision, flexibility, and robust diagnostics. They also needed a single-source manufacturer who could design, build, program, and commission the entire system—ensuring full accountability and a consistent approach across all equipment.

Maintaining production was critical. The customer wanted the ability to service or maintain individual lines without affecting the rest of the network, while also preparing each line for future expansion such as temperature monitoring, heat burnout detection, pulse outputs, and serial communication.

We were asked to deliver a complete, scalable, and forward-thinking solution.

The Challenge

- Outdated and unreliable weight-checking components

- Need for a unified, single-source manufacturing partner

- Multiple production lines requiring independent operation

- Requirement for future system expandability

- No modern interface for diagnostics or status monitoring

- Lack of a centralised method to view machine and network issues

- Need for precise weighing and counting of various cheesecake products

The customer required a modern, expandable control system—and a partner capable of designing every aspect, from concept to commissioning.

Our Solution

We engineered a complete, fully integrated system designed for accuracy, reliability, and future growth

1. System Design & Problem-Solving

Working closely with the customer, we designed a machine that could count and weigh multiple cheesecake varieties.

We developed solutions to each challenge raised during the design process, ensuring the system met all performance and operational requirements.

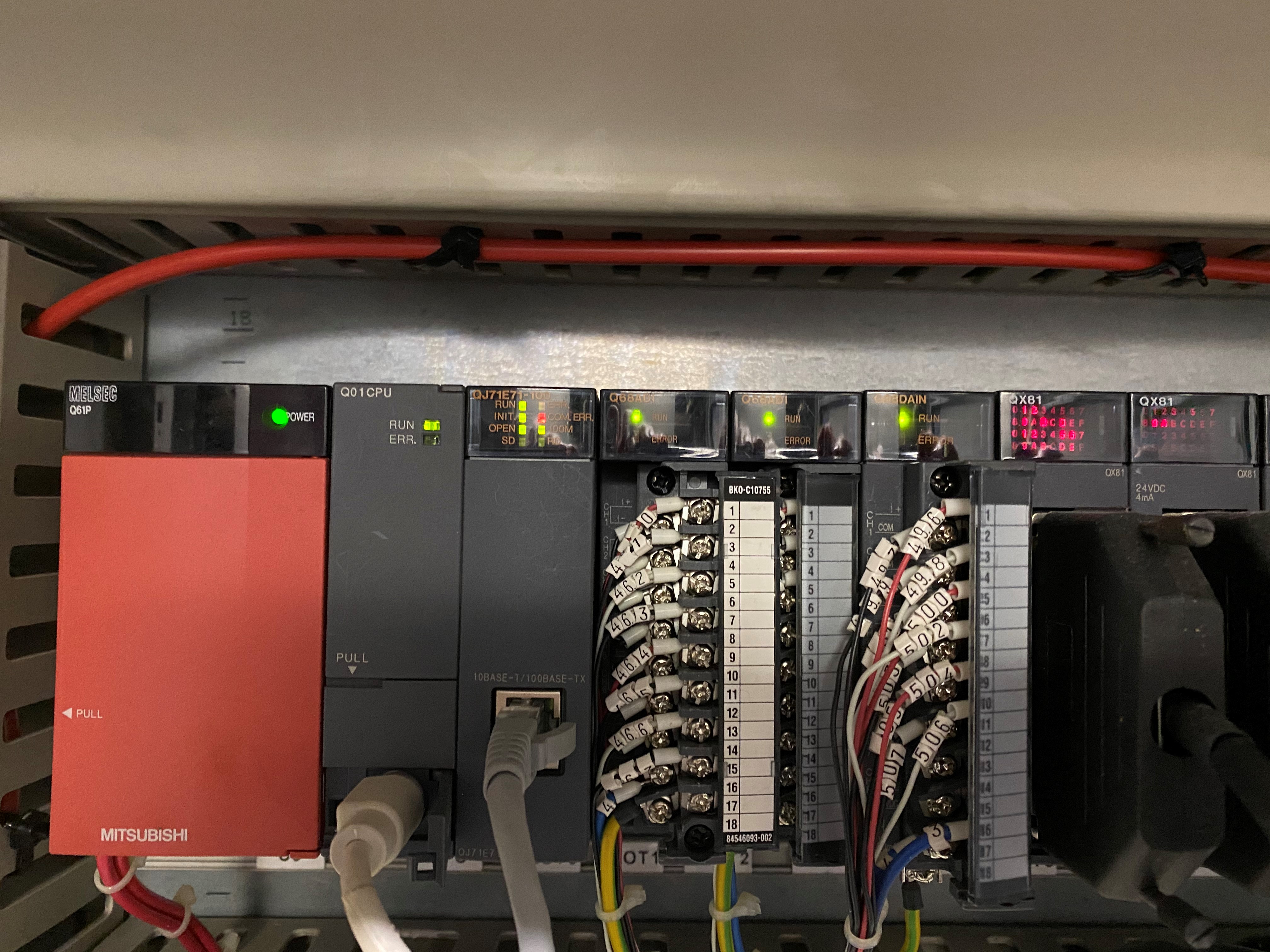

2. Scalable Multi-Line Architecture

Each production line was designed to operate independently, allowing maintenance or downtime on one line without interrupting the rest of the network.

Lines were also prepared for future expansion, supporting:

- Temperature sensor outputs

- Heat burnout detection

- Pulse outputs

- Serial communications

- Additional I/O and monitoring hardware

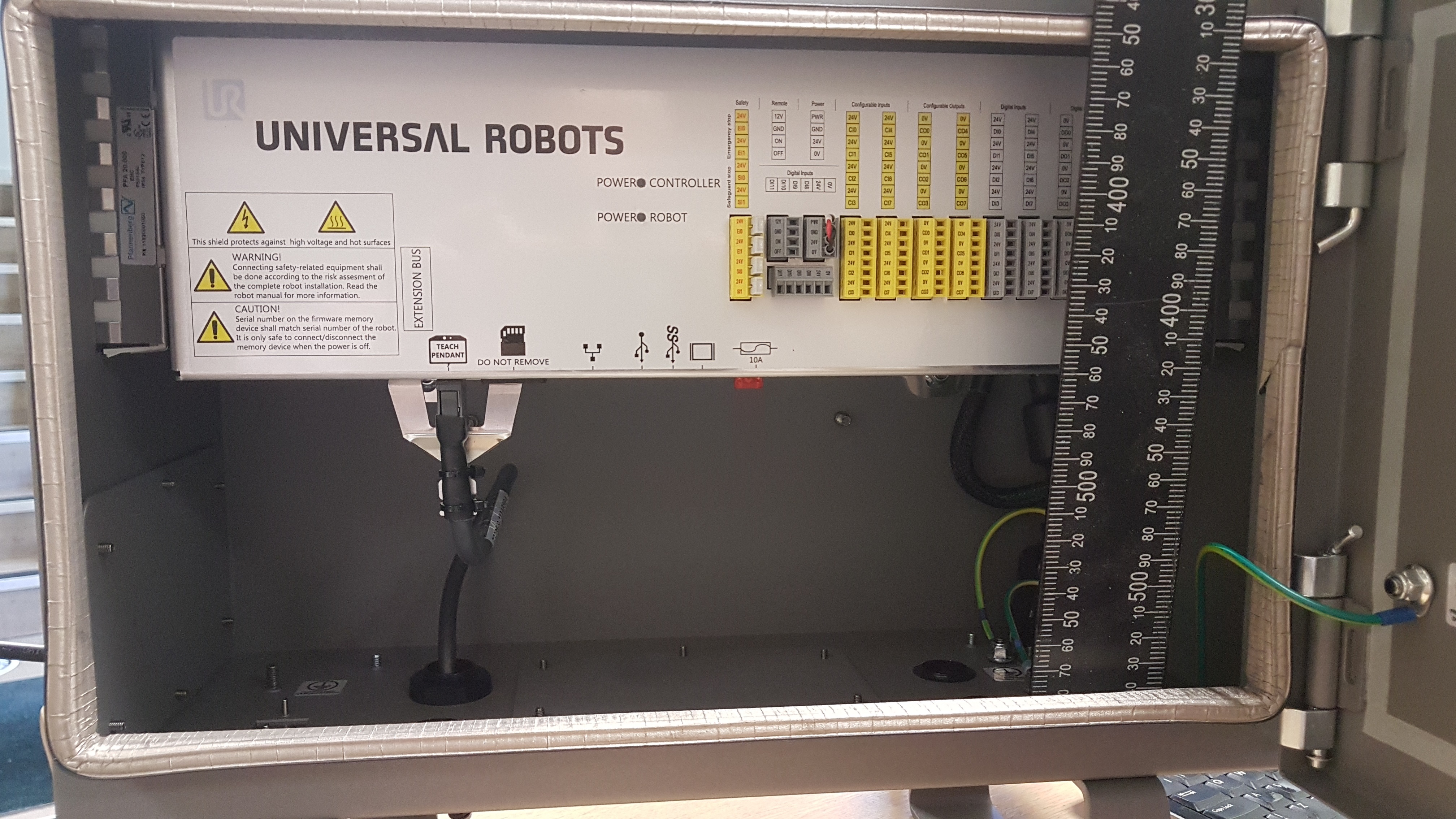

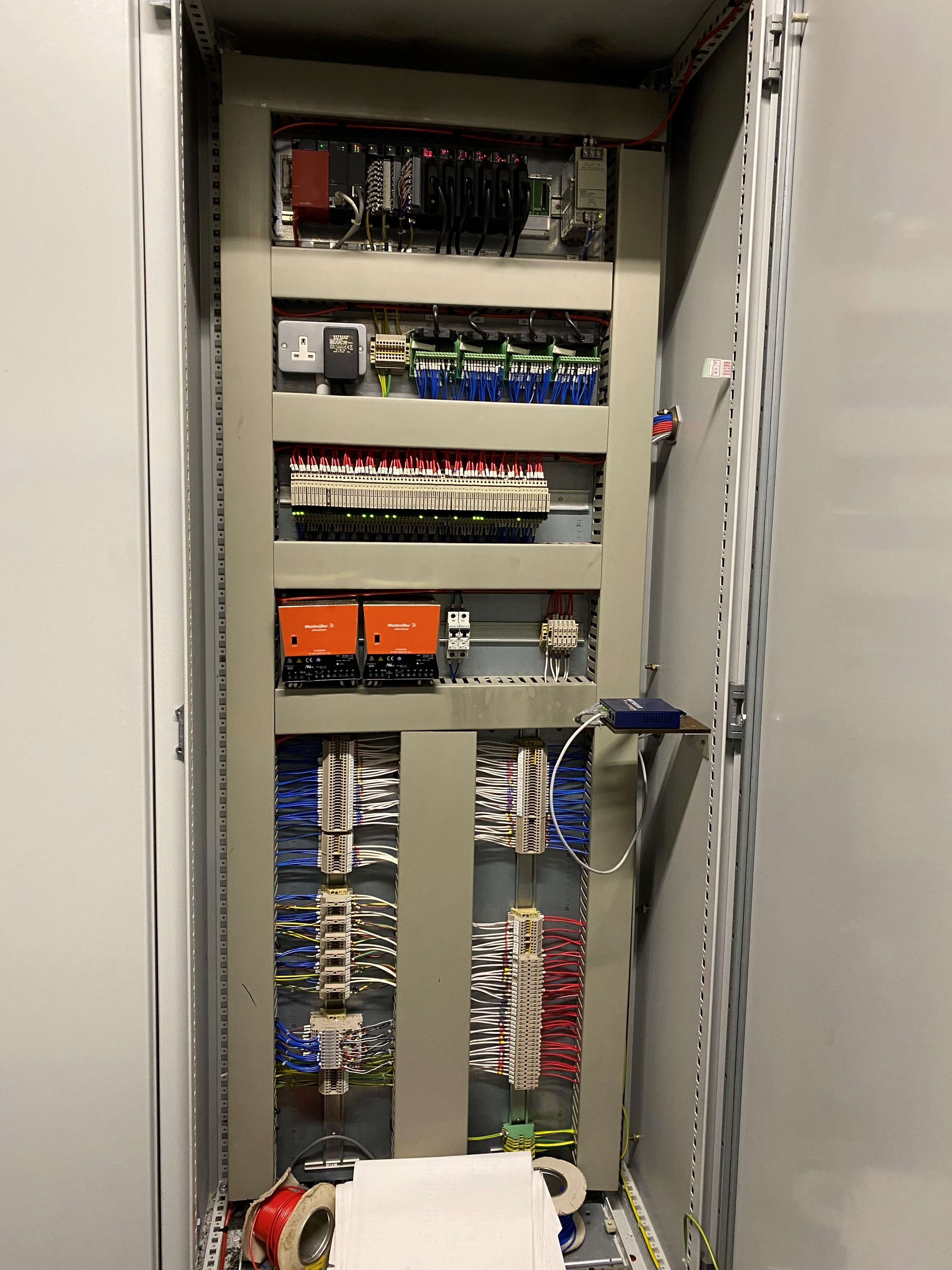

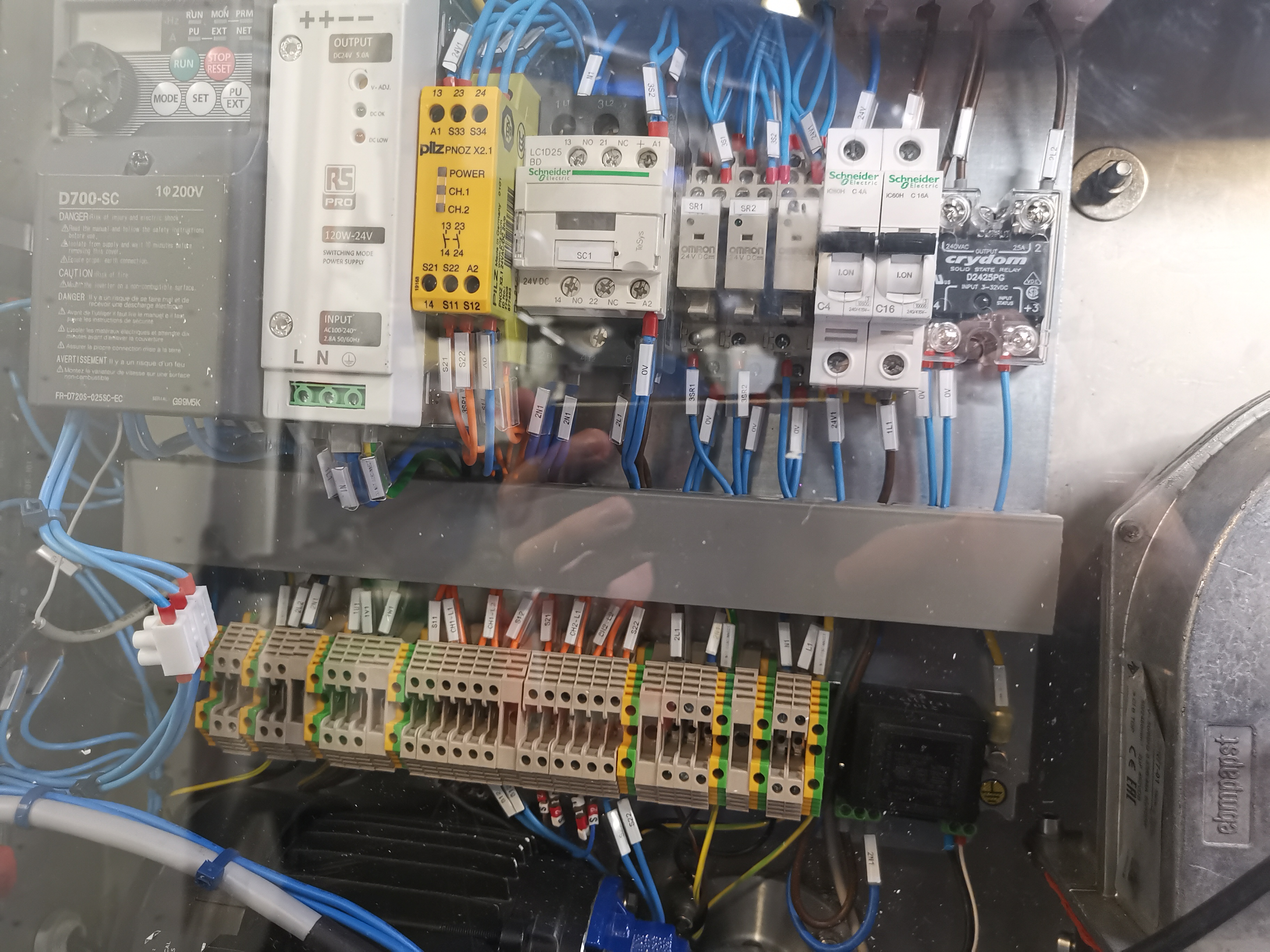

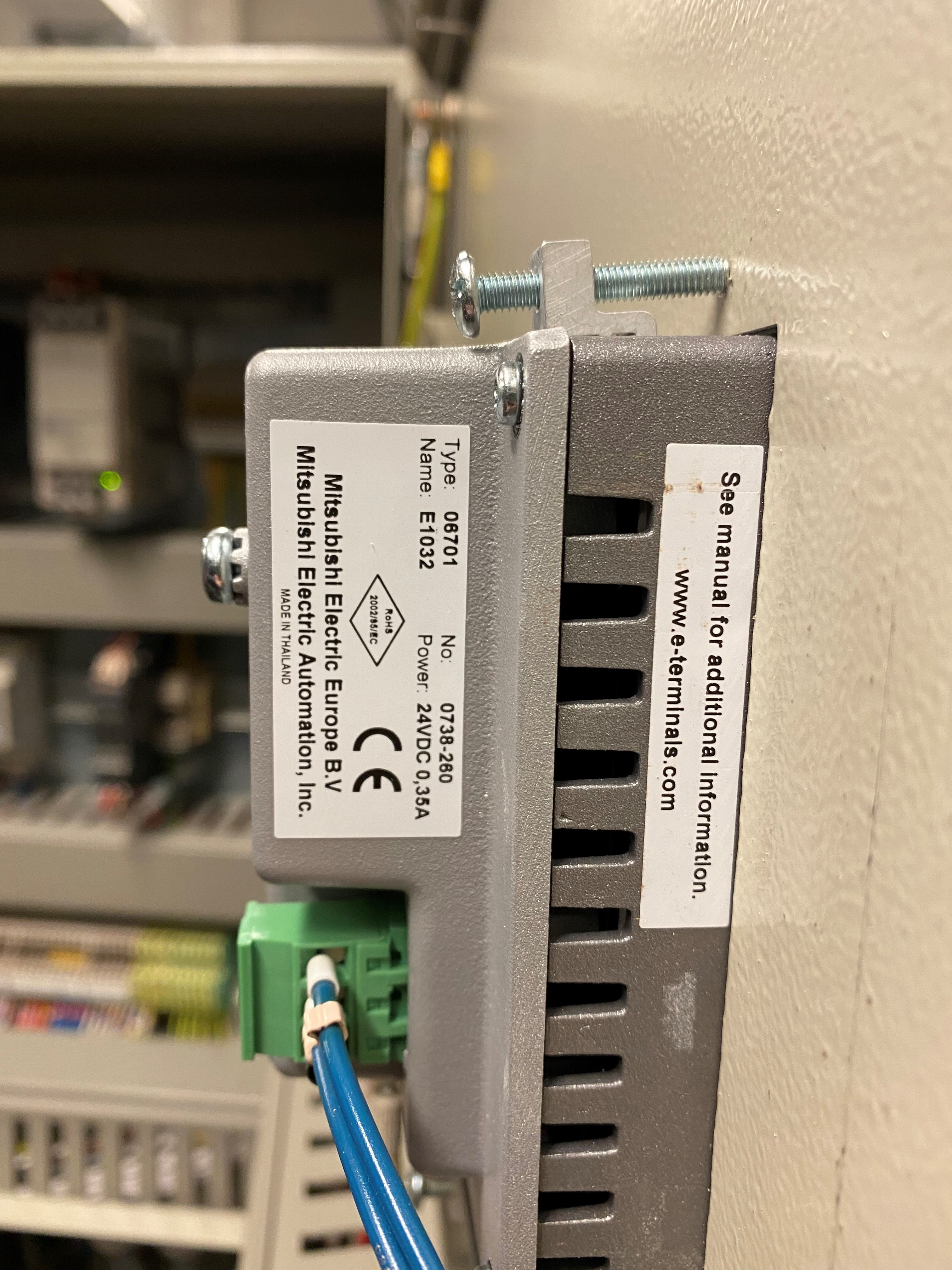

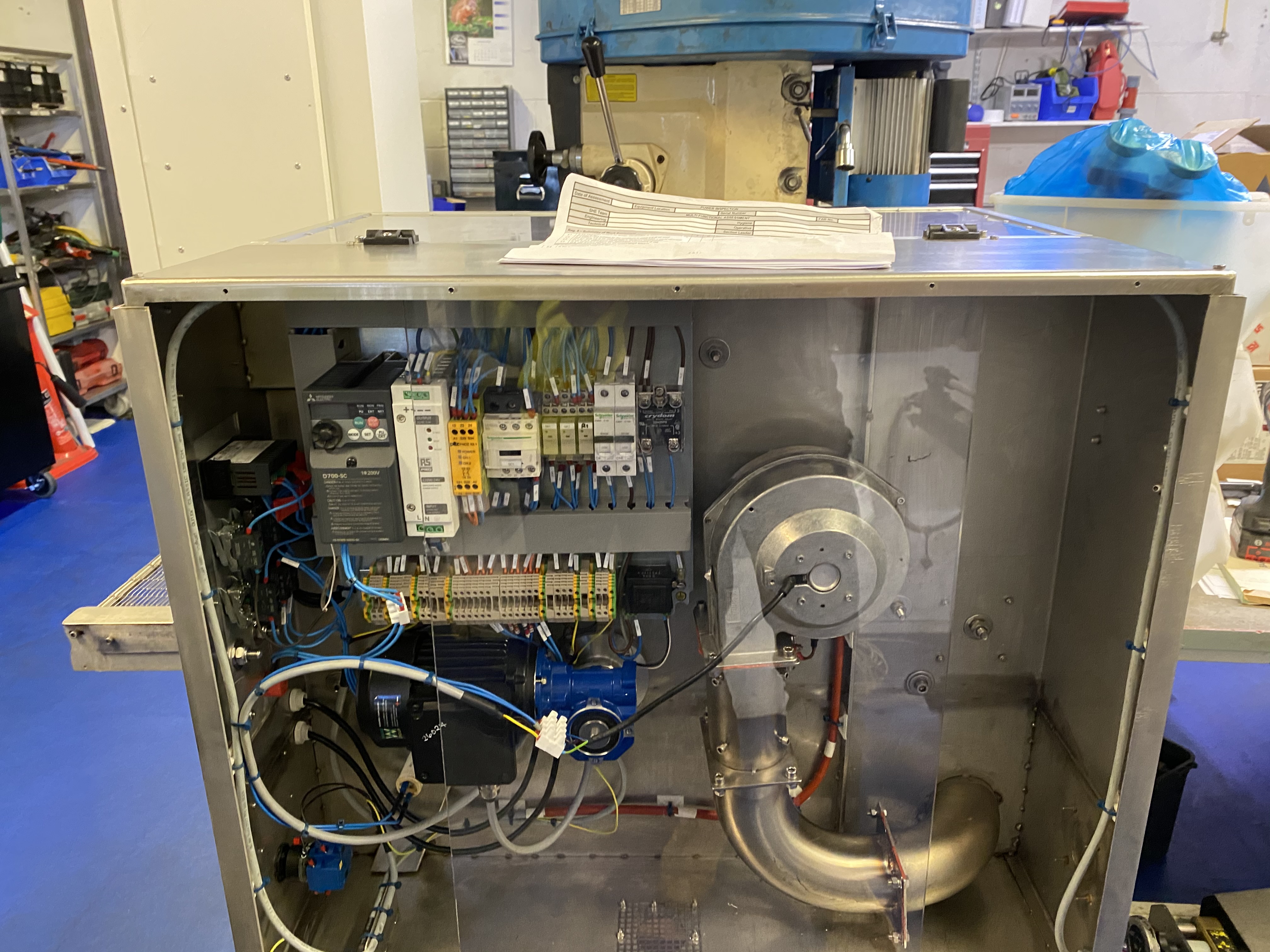

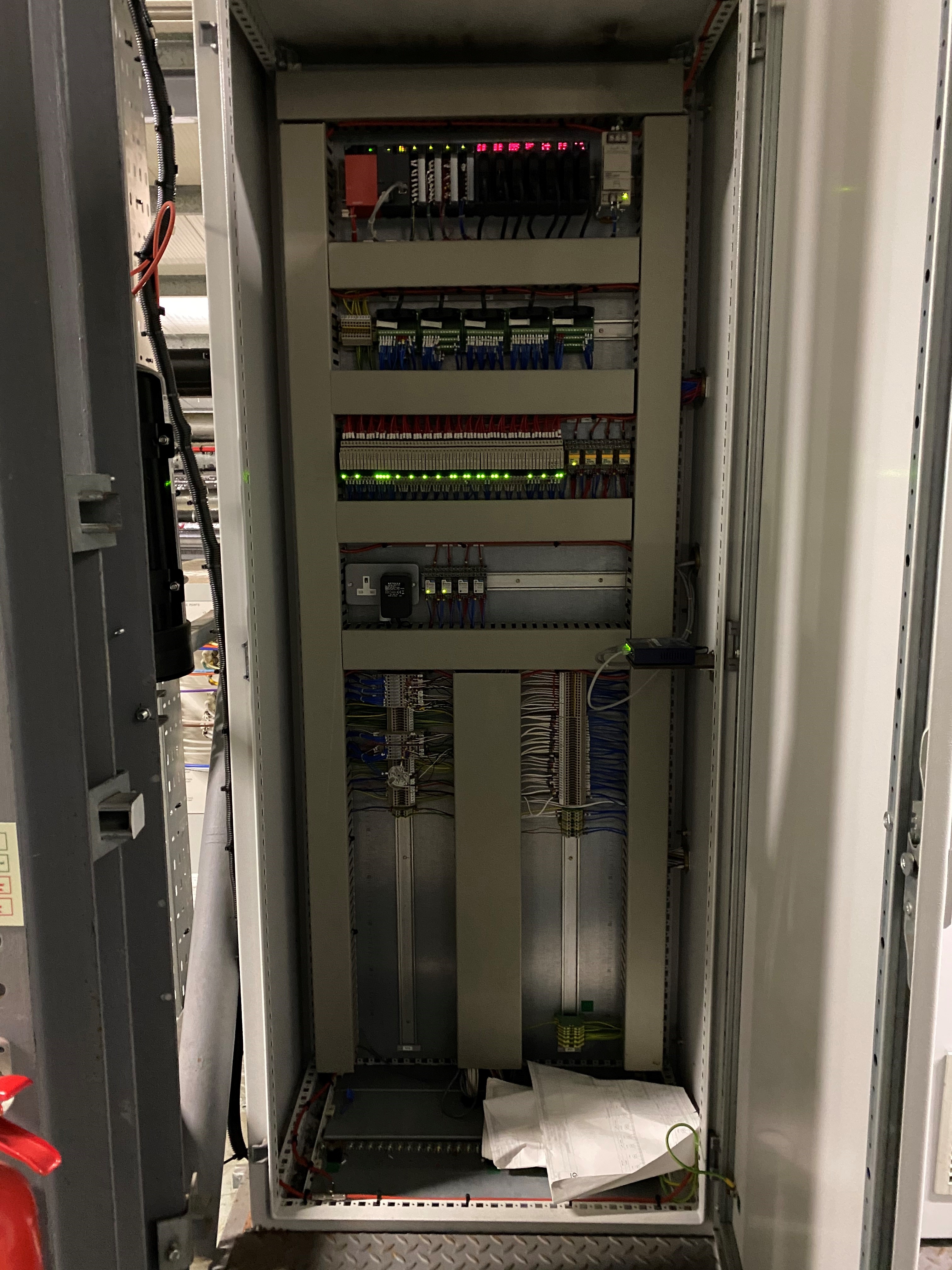

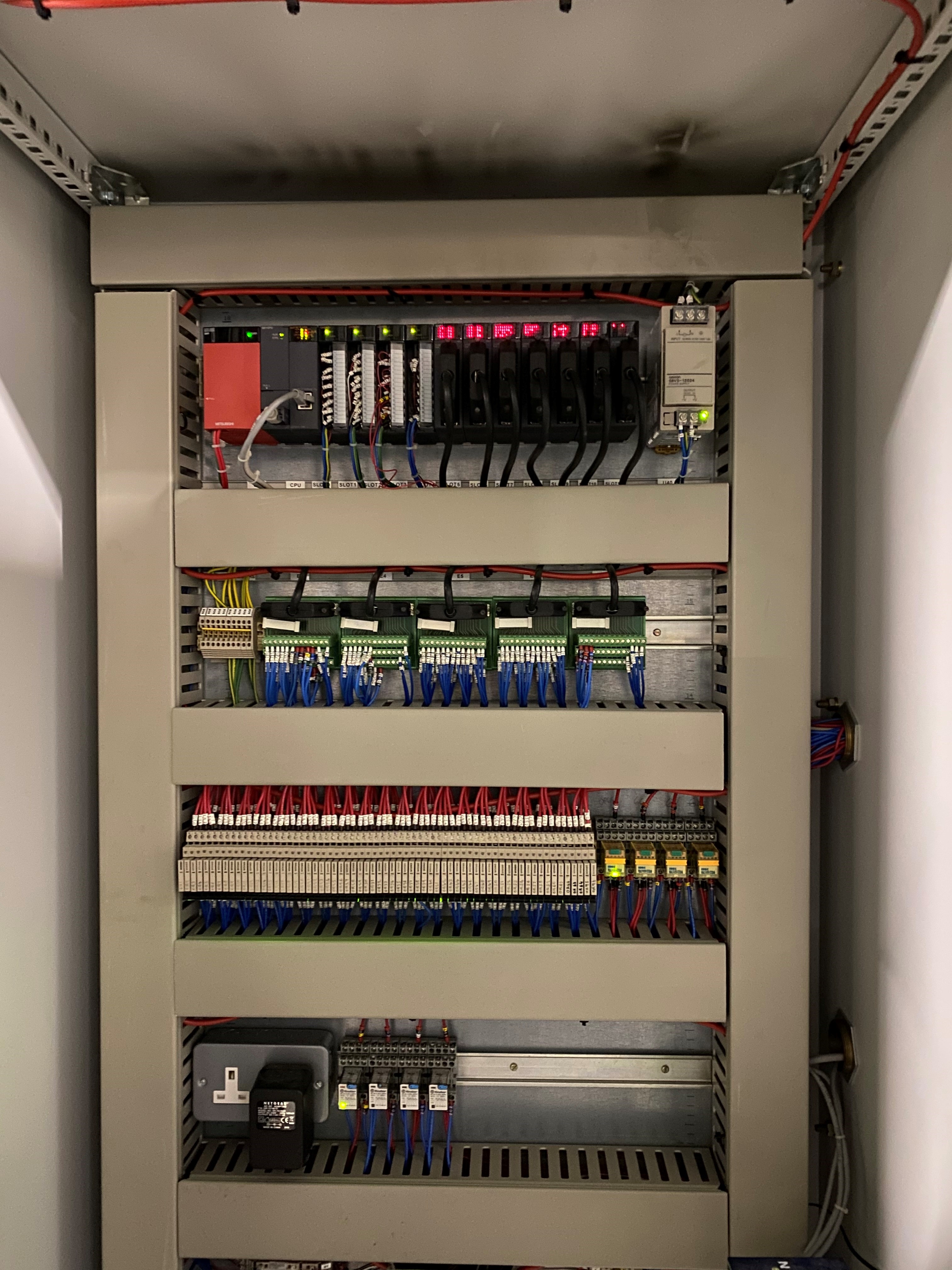

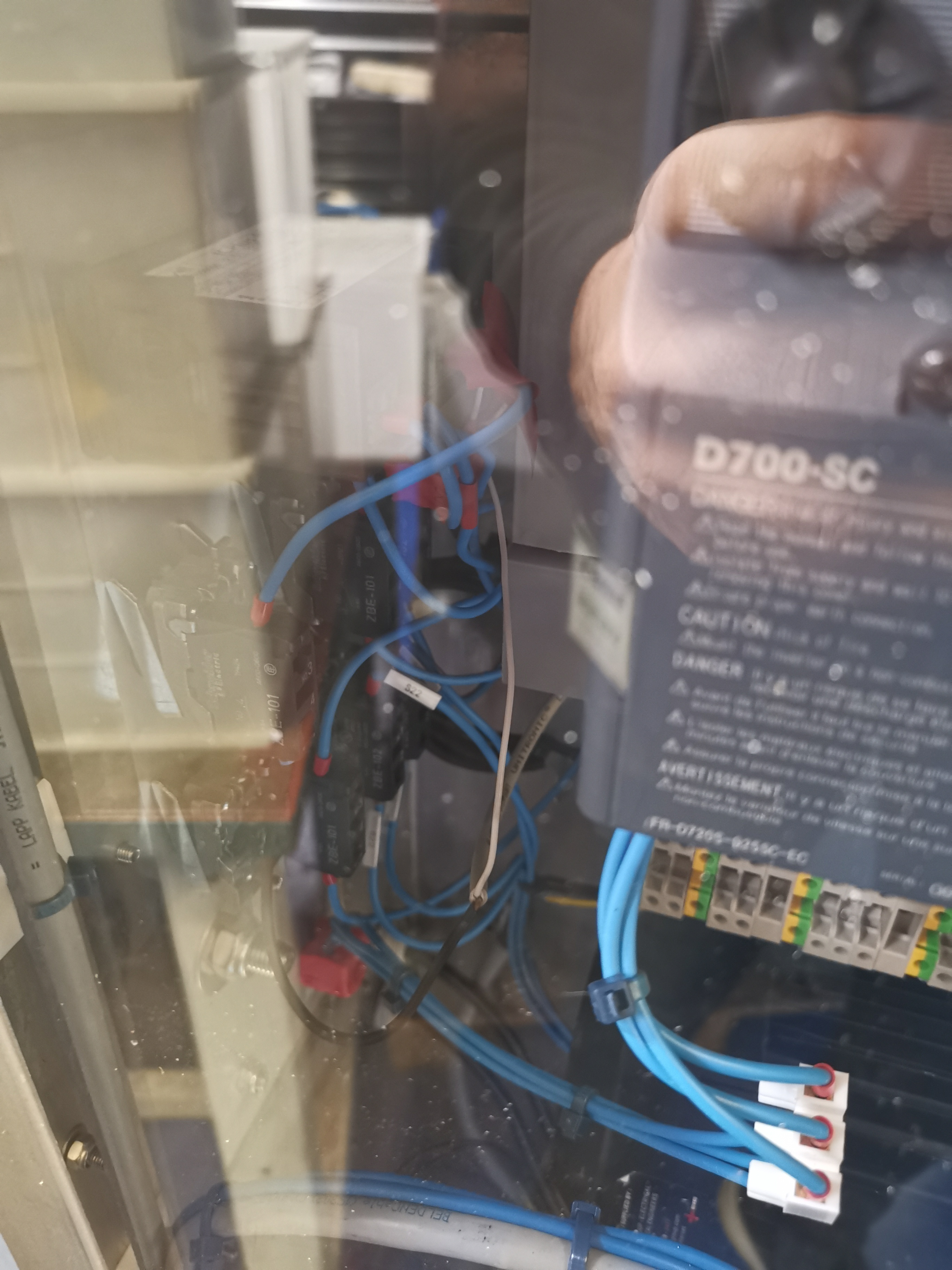

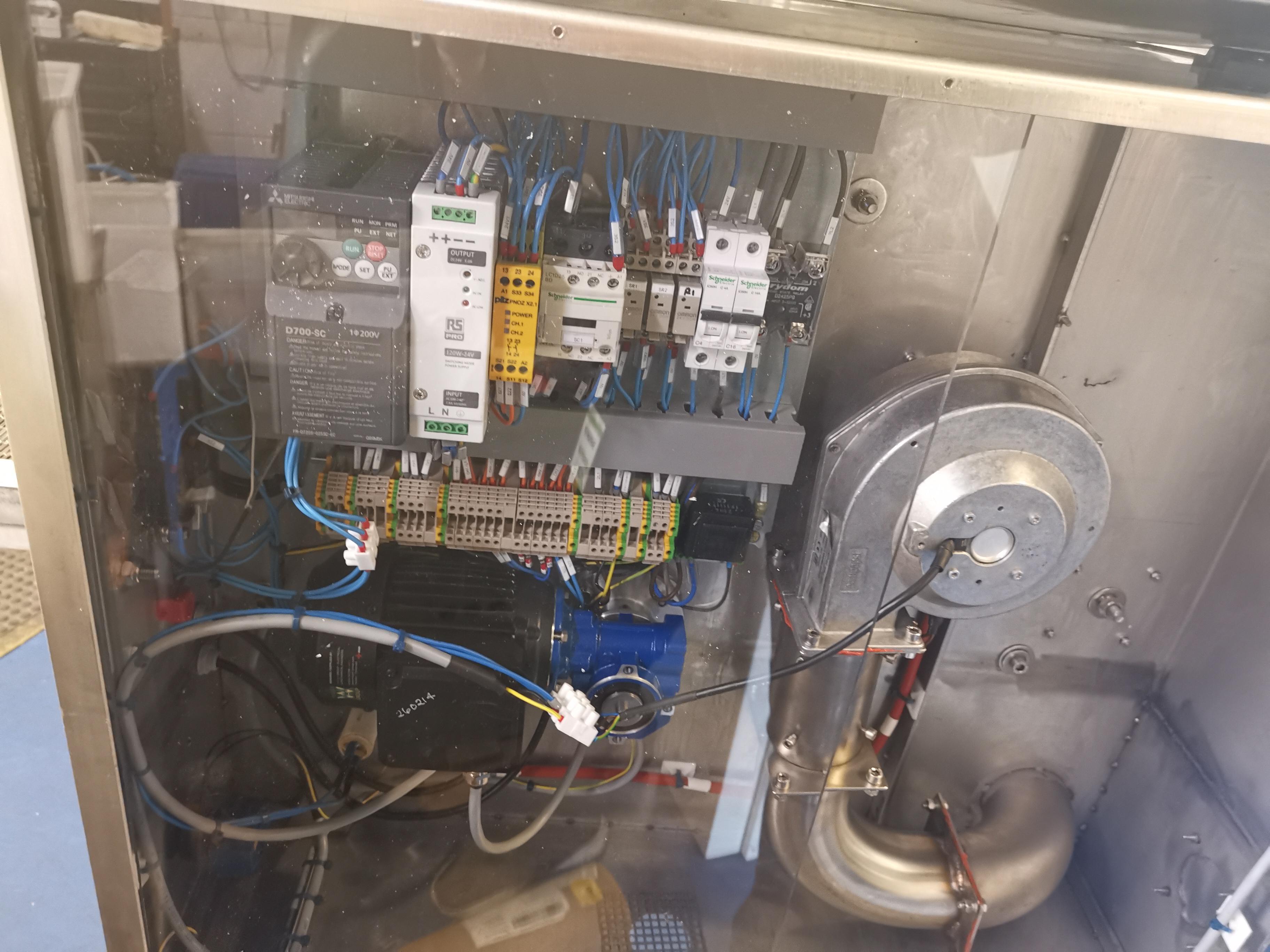

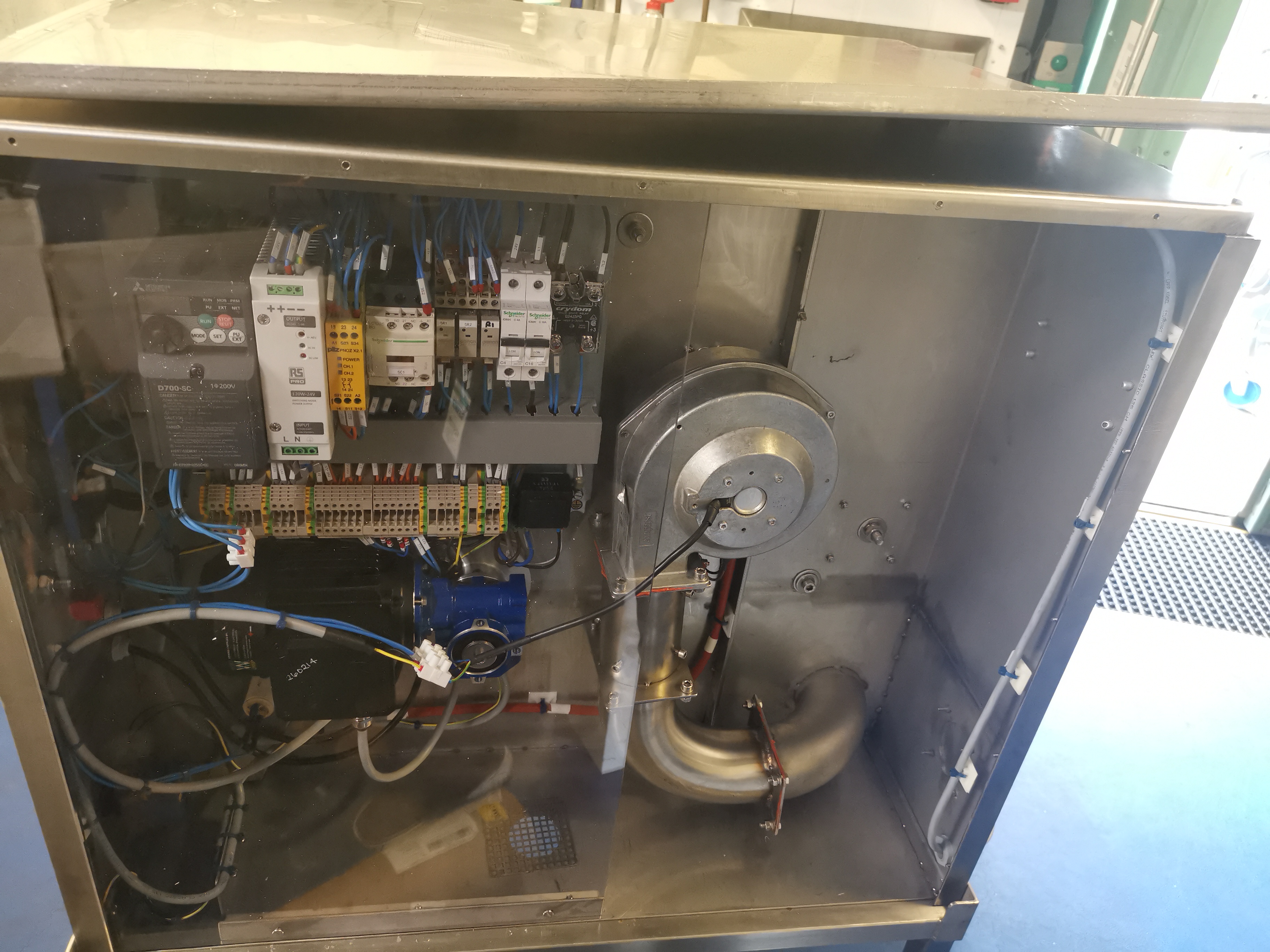

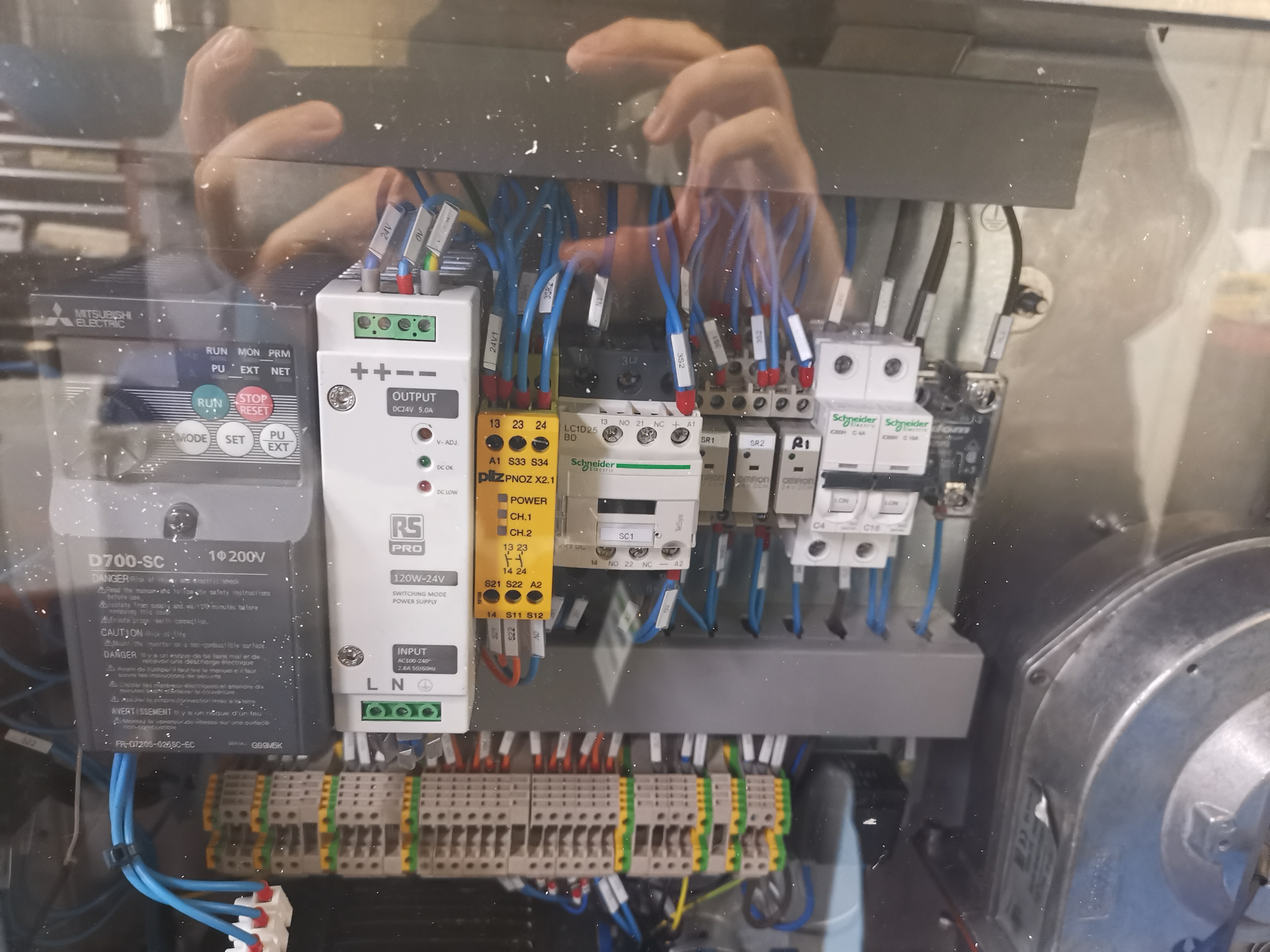

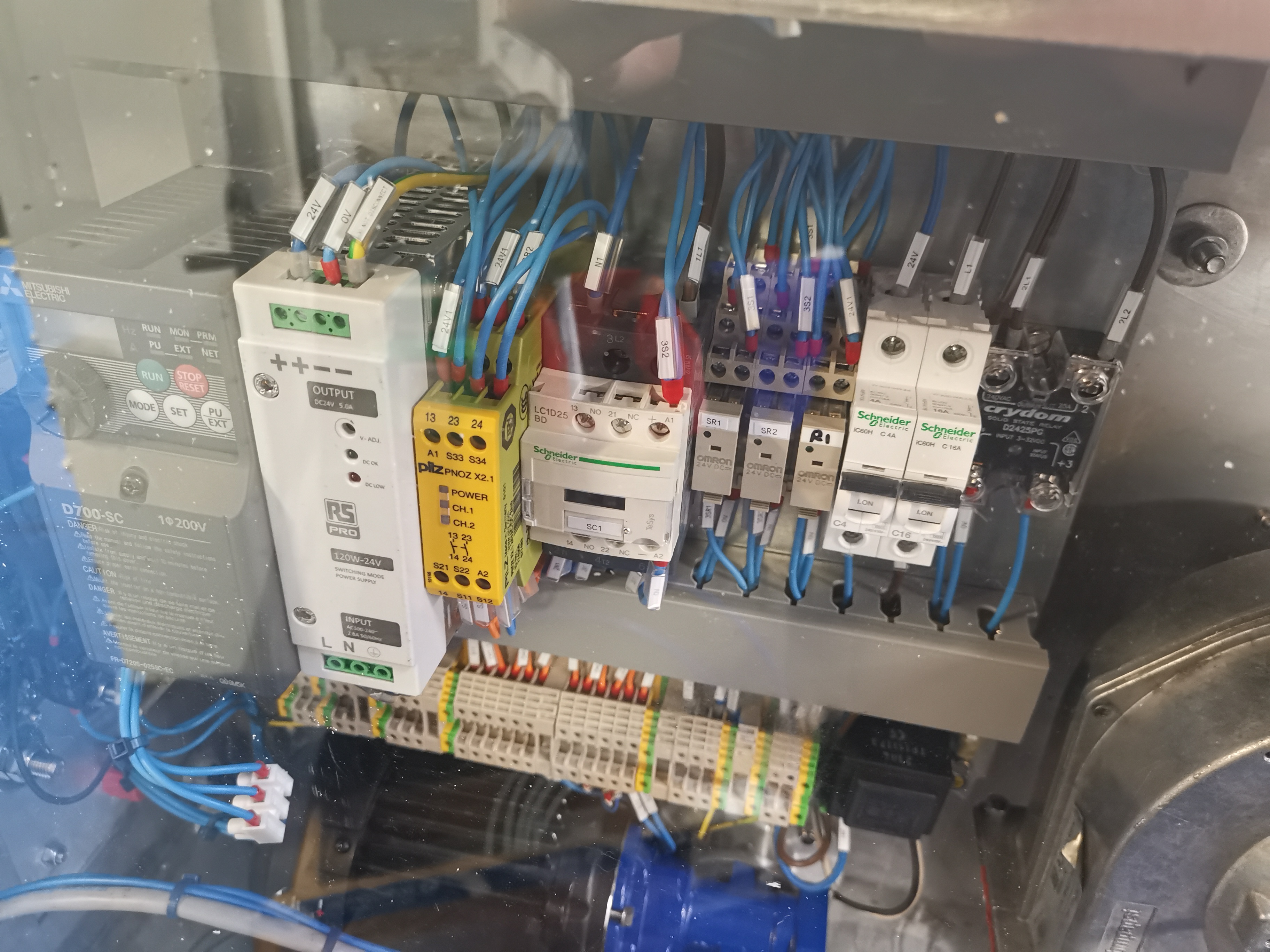

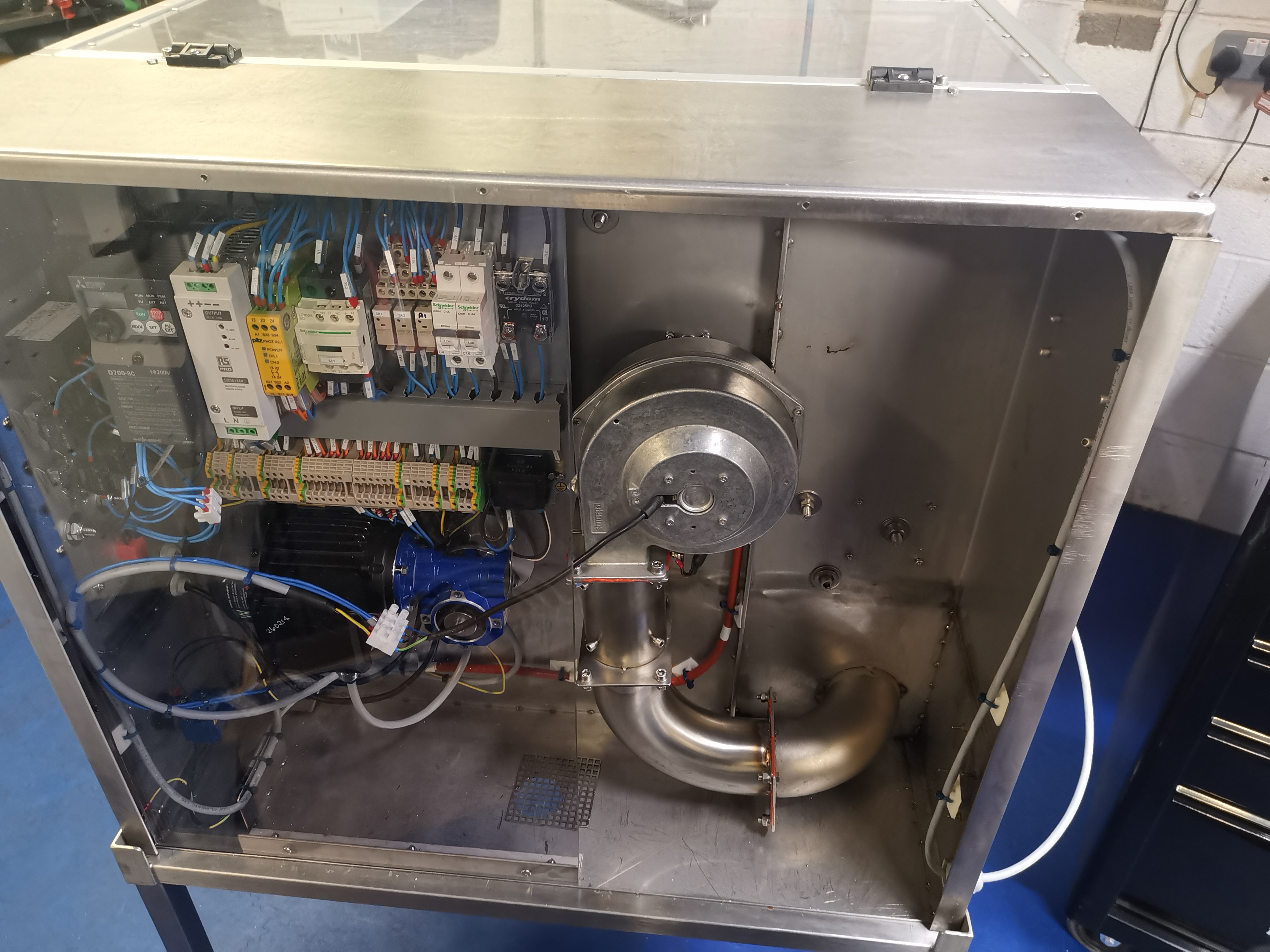

3. Complete Control System Upgrade

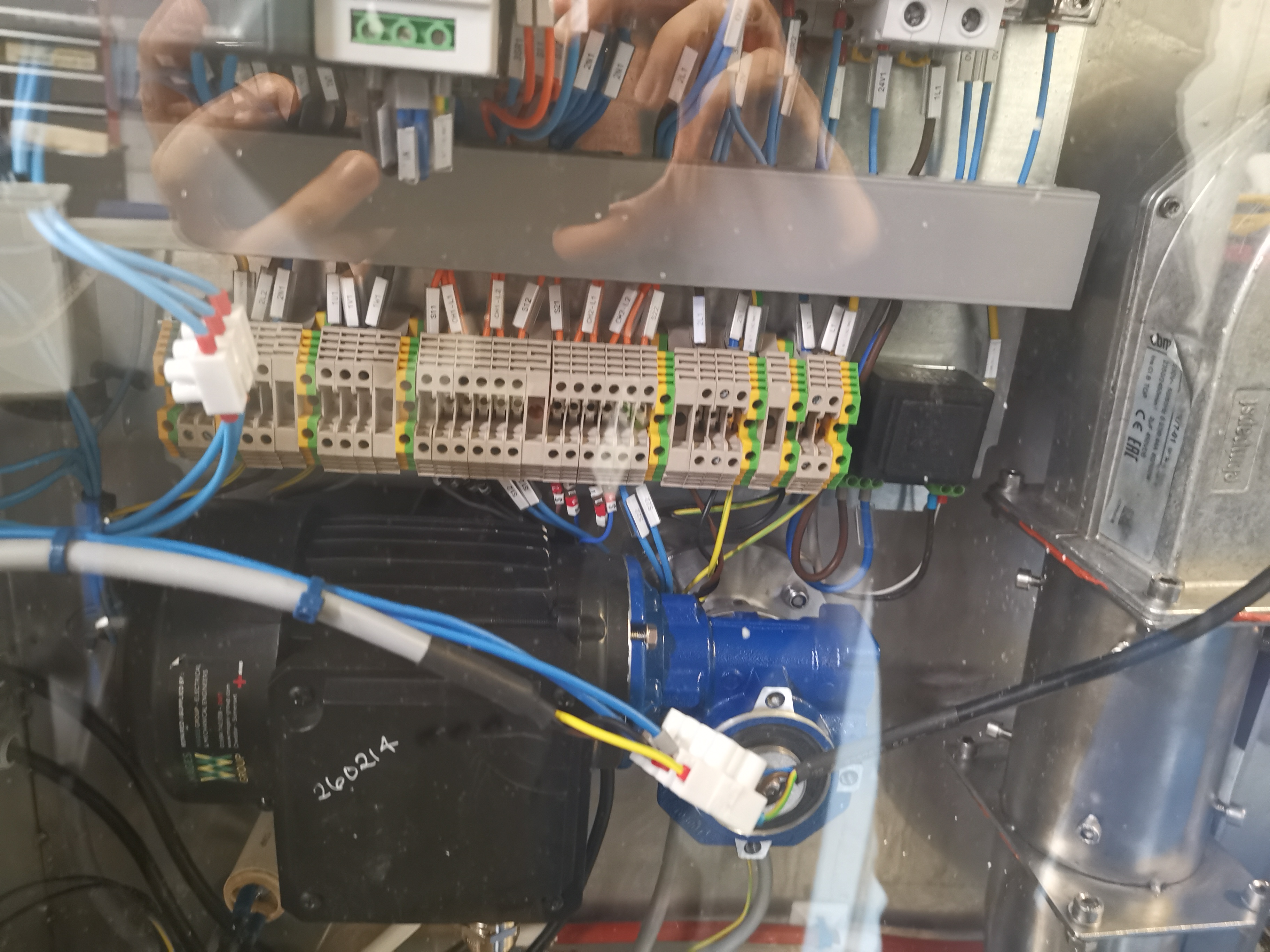

We installed a new PLC-based control system featuring:

- Advanced load cells for accurate weight measurement

- Signal conditioning for stable, repeatable readings

- Precise logic for count verification

- Dedicated PLC functions for per-line operation

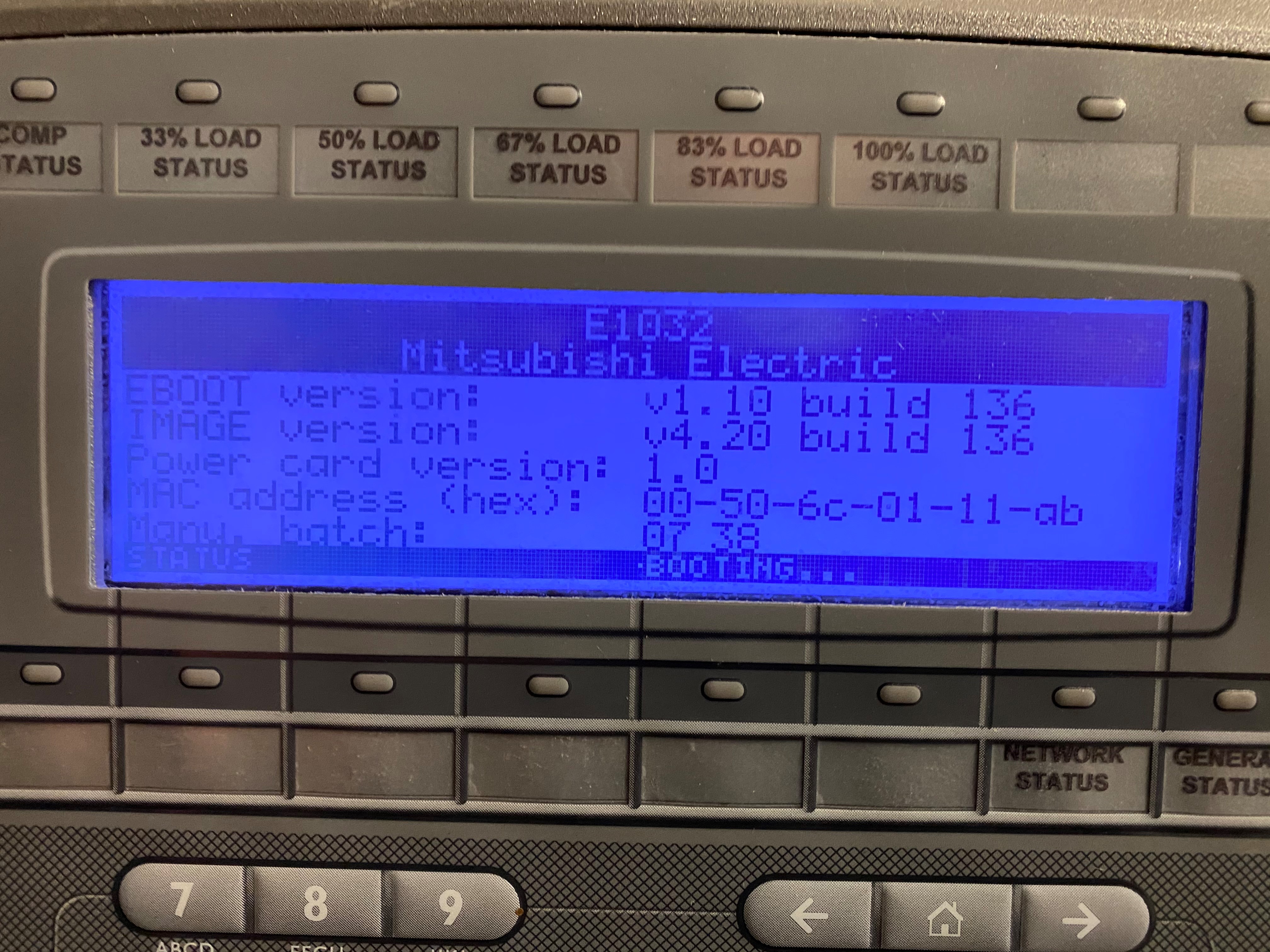

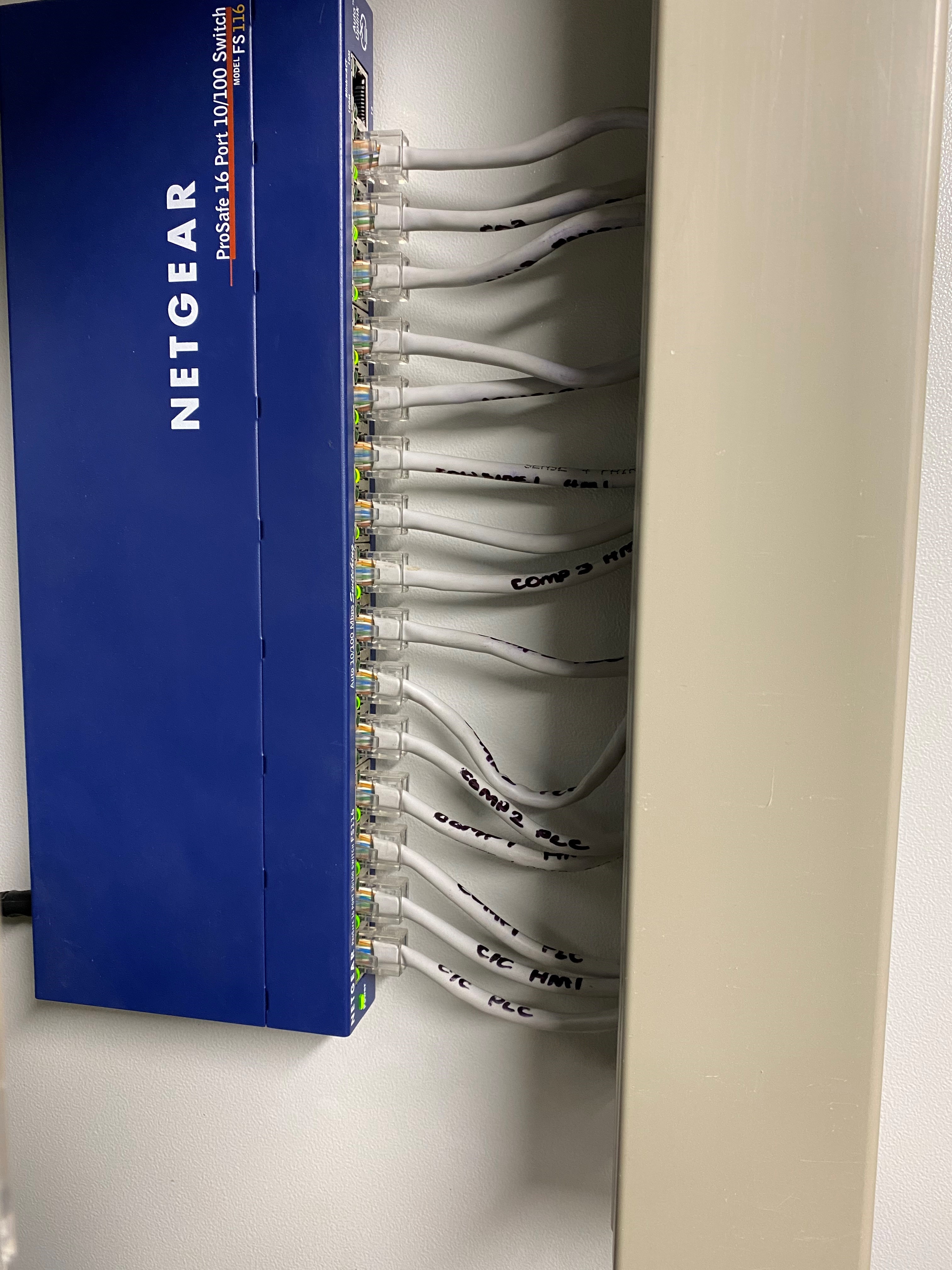

4. HMI Integration Across the Network

We programmed eight HMIs, providing:

- Live weight and count data

- Calibration and configuration tools

- Individual line status

- Clear pass/fail indicators

- Simple, intuitive navigation

- Engineering-level HMIs displaying system-wide issues and statuses

This gave operators and engineers complete visibility of the entire network.

5. Electrical Design & Installation

We delivered a full electrical engineering package, including:

- Engineering drawings

- Electrical schematics

- Cable schedules

- Supply and installation of all cabling

- Clear labelling and documentation

Every detail was designed for reliability, maintainability, and future adaptability.

The Result

The upgraded system now provides the customer with:

- Highly accurate weighing and counting

- Independent operation of each line, reducing downtime

- Fully scalable architecture ready for future enhancements

- Clear, centralised diagnostics across eight HMIs

- Reliable, modern hardware replacing outdated components

- Reduced rejects, improved efficiency, and easier troubleshooting

- A complete solution delivered by a single-source manufacturer

This upgrade brought the weight-checking and counting process up to modern standards—efficient, accurate, and ready to grow with the customer’s production needs.

Contact Us

Get in touch using the form below.